Because the plant floor has switched to get a lot more carefully connected, the written text among robots and machine vision has converged in a solitary, consistent stage, setting the phase for the following day of more and more more responsive vision-driven automated frameworks. BitFlow, Corporation., an worldwide pioneer in casing grabbers contained in mechanical imaging, predicts vision-introduced robots can be a standout among possibly the most difficult forces in every aspect of assembling using the following decade.

“Because the 1960s robots have place in robotization forms, yet they have done consequently generally visually impaired,” pointed out Donal Waide, Director of Sales for BitFlow, Corporation. “Vision-equiped robots are unique. Presently, very similar as being a human laborer, robots can see an explicit part to approve whether it is being set precisely within the pick and hang application, for example. Cost reserve funds will most likely be acknowledged since less hard fixturing is needed along with the robot is more and more more adaptable within the chance to locate a selection of parts through an identical equipment.”

HOW Automatic VISION WORKS

Utilizing a mix of camera, links, outline grabber and programming, an illusion framework will distinguish a little, its introduction that is relationship for that robot. Next, this publish is sustained for that robot and movement starts, for instance, pick and hang, meet up, screw driving or welding errands. The vision framework will likewise catch data that may be generally difficult to acquire, including little restorative subtleties that enable the robot know setup part is worthy. Mistake sealing decreases pricey quality issues with products. Self-support is the one other advantage. If arrangement in the instrument is off because of harm or put on, vision pays back by performing machine balance change monitors an excellent intermittent premise since the robot is running.

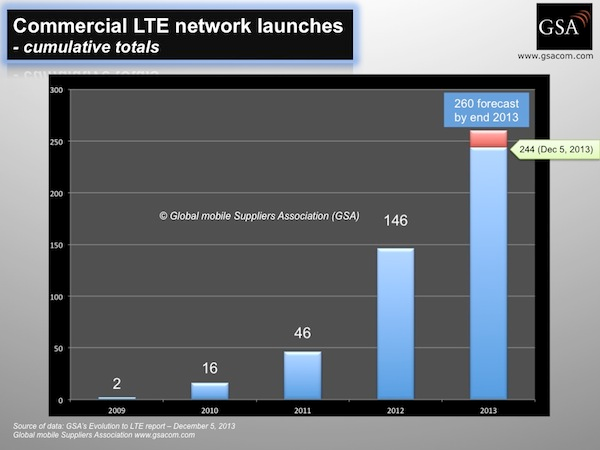

Double MARKET GROWTH

In shouldn’t shock anybody the unit vision and automatic financial markets are moving pair. As proven with the Association for Evolving Automation (A3), robot handles The united states . States a year ago outperformed every history. Clients bought 34,904 aggregate units, talking to $1.896 billion in absolute deals. Within the interim aggregate machine vision exchanges within the united states . States expanded 14.8%, to $2.262 billion. The car business represents appoximately 1 / 2 of aggregate deals.

Negligence FRAME GRABBERS

Advancements in how vision-introduced robots see and respond to their surroundings are really what makers are trying to find since they create mechanization frameworks to enhance quality, profitability and price efficiencies. These types of headways rely on casing grabbers being matched wealthy in-goals cameras to digitize simple video, in this way altering within the information having a shape which can be created by programming.

BitFlow has reacted for that demands within the mechanical technology industry by presenting outline grabbers in line with the CoaXPress (CXP) machine vision standard, right now the fastest and a lot of incredible interface available. In mechanical autonomy applications, the 5 to 7 meters confinement in the USB link association is deficient. BitFlow CXP outline grabbers permit around 100 meters relating to the casing grabber along with the camera, without any misfortune in quality. To limit cabling expenses and intricacy, BitFlow outline grabbers require just a solitary little bit of cajole to supply rapid information, and additionally to provide control and send control signals.

BitFlow’s newest model, the Aon-CXP outline grabber, is ideal for streamlined coordination in a mechanical autonomy framework. Although little, the Aon-CXP could possibly get 6.25 Gb/S price of understanding over its single connection, double this present reality information rate within the USB3 Vision standard and basically faster when compared with newest GigE Vision information rates. The Aon-CXP should be utilized with another arrangement of single-interface CXP cameras which are littler, less pricey and cooler running than past models, making them perfect for mechanical autonomy.

Comments